Old Wood: 160 Year Pandora Mill White Pine

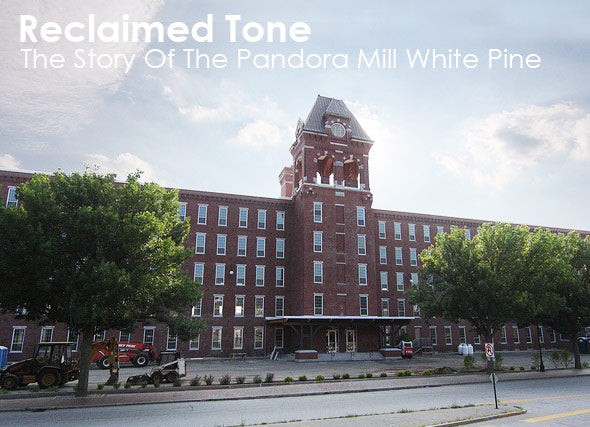

In Manchester, New Hampshire stands an enormous 19th Century brick building that is helping to give birth to a new generation of fine guitars. Not because any are assembled here, in fact nothing has been made here for decades. The Pandora Woolen Mill was built in 1845 as part of the rapidly growing textile industry, and was pumping out 60,000 sweaters a year until 1990. Now the building is undergoing an extensive renovation and historians have salvaged some very interesting wood from inside the Pandora Mill, which was extensively reinforced with giant White Pine beams. These beams have all been reclaimed, and the best beams were selected to be milled for fine musical instruments. Follow the jump for more history of the old Pandora Woolen Mill White Pine that is breathing new life into the next generation of guitars.

The Music Zoo is has commissioned a very special run of Charvel San Dimas guitars with bodies made from the Pandora Mill White Pine, paired with a Carbonized Maple neck. We’re super excited about these guitars. They are light, toneful and gorgeous. View them all here.

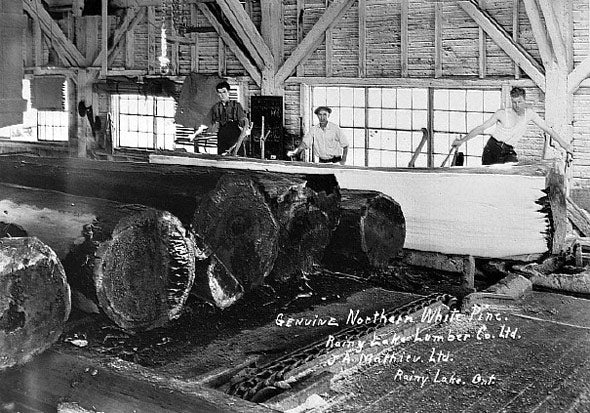

Above is a picture depicting a 19th Century sawmill ripping Northern White Pine, exactly the kind of huge logs that were used to build the Pandora Mill. The Pandora story has some rich history; what follows below was provided to us by the folks who are involved with the reclamation process:

In the first half of the 19th century, much of New Hampshire was being clear cut to graze sheep for the emerging textile industry. A breeding pair of Merino sheep had been smuggled under penalty of death from Portugal to New Hampshire, and a wool industry was built beyond what the world had ever known. The first falls of the Merrimac River was situated proximate to good harbors, large labor pool, raw wool and inventive minds. New technologies such as circular knitting and power fulling were employed with great success. The Amoskeag Mill complex was built in the 1840s using native White Pine and other species from the upstream virgin forest, floated down rivers and milled on site to build what became by mid century the largest mill complex in the world at over 1.5 miles along the Merrimac River at Manchester. In 1845 a section of the mill was built which became the Pandora Woolen Mill. At its height, Pandora Industries employed over 1,000 people producing 60,000 sweaters per year, more than anyone else in the world. In 1990 the mill closed due to offshore competition. The buildings stood vacant until purchased and repurposed by Dean Kaman, an enterprising engineer. AutoDesk and other high technology firms now occupy what was once the largest water-powered textile mill in the world.

In 2008 some of the buildings were deconstructed to allow better access to various parts of the complex. The beams were transported and stored at an Amish farm near Lancaster Pennsylvania. In 2010, Northwind purchased all the tonewood grade beams, measuring 14″ x 16″ x 24′ to 36′ long, native first-growth White Pine. The wood grew from early colonial times, sometimes as early as 1600 in the natural pre-industrial forest.

In 2008 some of the buildings were deconstructed to allow better access to various parts of the complex. The beams were transported and stored at an Amish farm near Lancaster Pennsylvania. In 2010, Northwind purchased all the tonewood grade beams, measuring 14″ x 16″ x 24′ to 36′ long, native first-growth White Pine. The wood grew from early colonial times, sometimes as early as 1600 in the natural pre-industrial forest.

We began resawing into various components including acoustic soundboards and electric guitar bodies. Approximately 20,000 board feet of beams were resawn yielding about 30% tonewood and the remainder used for various less demanding applications. This old-growth wood is considerably stiffer than new White Pine. It produces clean, clear overtones from very light weight. Among the tonewood produced have been high-end archtop guitars, fiddles, mandolins, acoustic guitars and bodies for Fender’s Telecaster turns 60 special edition. We are very pleased to make this unique offering to the musical instrument market.