Duesenberg Article: Guide To Nickel Hardware

As guitar players, we have become aware of how much nickel can become a tedious material to work with as time passes. The progressive dulling of nickel over time begins to eat away at our desire to look at our guitars (unless of course that’s the look your going for). Furthermore, being a Duesenberg dealer certifies our awareness of the everlasting nickel fading. If you’ve become victim to this guitar-demic, read the advice column our friends at Duesenberg put together to solve the world’s nickel issues.

the following article is from Duesenberg-

Working in customer support, we receive a lot of questions like

Hey, why are the chrome parts on my starplayer already getting dull?

Well, to answer that question it’s important to understand a few things but it basically comes down to

It’s not chrome, it’s nickel.

This is the Duesenberg Guide to Nickel Hardware

There are a few types of hardware finishes around with chrome being the most popular one and nickel being used rather rarely these days. Of course there are also other finishing methods resulting in different types of gold, black and other hardware colours. However, since Duesenberg Hardware is often mistaken as being chrome finished, let’s focus on the difference between both.

What is Nickel & Chrome?

There are different stages in metal finishing, all resulting in a certain coat which is applied in layers on the base material. The base material (like brass, aluminium etc.) firstly is coated with a very thin layer of copper which acts as a sort of primer for the following layers.

After that, nickel can be applied to the workpiece. If you want to create a more robust and “easy-care” finish, you then apply a layer of chrome onto the already existing nickel layer. This whole process is called galvanisation – look it up, it’s pretty cool actually. So you could say a nickel finish is the pre-stage of a chrome finish.

Why Nickel then?

A nickel finish has some very distinct characteristics which other finishes do not have.

From the historical point of view one might say that it is the “oldschool way to do hardware finishes”. They say Leo used nickel finishes on his first instruments, simply because the process was cheaper and faster, but he also mixed nickel parts with chrome ones. At some time, guitar manufacturers stopped using nickel as their primary hardware finish, mainly because chrome finishes give you a more durable hardware which can withstand a lot of wear and tear. Nickel hardware starts to become dull rather quickly if not properly taken care of.

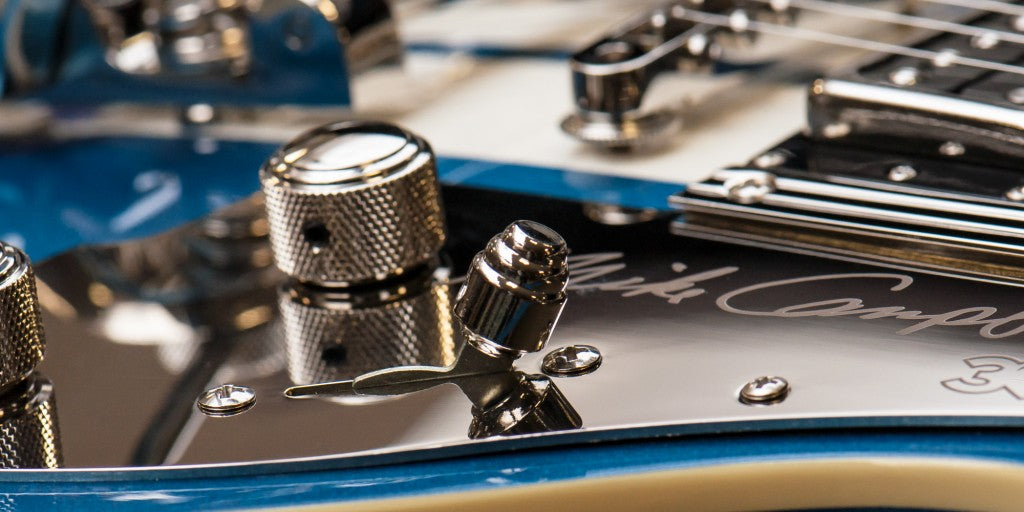

However, this is exactly the look that vintage guitar enthusiasts love about their nickel finished hardware and could not be achieved with a chrome finish. Having said this, there is something else which makes a nickel finish special from an aesthetical point of view, which also is the main reason to go for nickel in the first place. While chrome shines blueish and cold, nickel has a unique, beautiful, classy, golden and warm sheene to it. In direct comparison, most people even find the chrome finish looking “cheap”, which is subjective, of course.

How to take care of Nickel Finishes

If you are one of the people who do not like the worn, dull style of aged nickel hardware, here is some advice for you to keep the hardware on your Duesenberg in good condition:

- clean off the hardware regularly depending on how much you play

- clean the entire hardware after a gig or extensive sessions

- NEVER store the instrument damp (moisture/sweat) in its case for an extended period of time

Nickel is prone to age quickly if you have an aggressive hand sweat, which some people have, in fact most people. Tuner buttons, Pot Knobs and the area on which your hand rests on the bridge while palm muting are pretty likely to show the first signs of tarnishing. It’s not bad for the hardware though. Apart from the aged look which some people might find unappealing,

there are no downsides to worn nickel hardware. But if properly taken care of, you can maintain the beautiful sheen on your hardware for quite some time. The instruments shown below are roughly the same age, one being played exessively and cleaned probably infrequently, the other one being treated with kid gloves. Both sound amazing.

You can use regular guitar cleaning products for maintainance. For our own hardware, we recommend our own Duesenberg THE CLEANER. It is a solvent free, biodegradable cleaning product which also protects the lacquer on your instrument from fingerprints and dust.

For heavily aged hardware, you can also use some soft metal polishes to get rid of heavy tarnishing or spots. You should however not use it regularly for normal cleaning purposes because you might start to rubb off the nickel if used regularly for years.

So this is what it’s about.

The decision for nickel is mostly an aesthetical one without technical downsides. It is a decision in favour of classic beauty which I personally believe should always be a bit demanding in order to move us to treat something with the amount of care it deserves.

You should be aware of how nickel behaves in order to be able to react to it to create the kind of finish you like.

I hope this guide has given you an idea of what the decision for nickel hardware is about.

Thanks for reading!

Best,

Andrej

Have a look at all of our Duesenberg guitars in stock here!

Read more interesting articles from Duesenberg here!